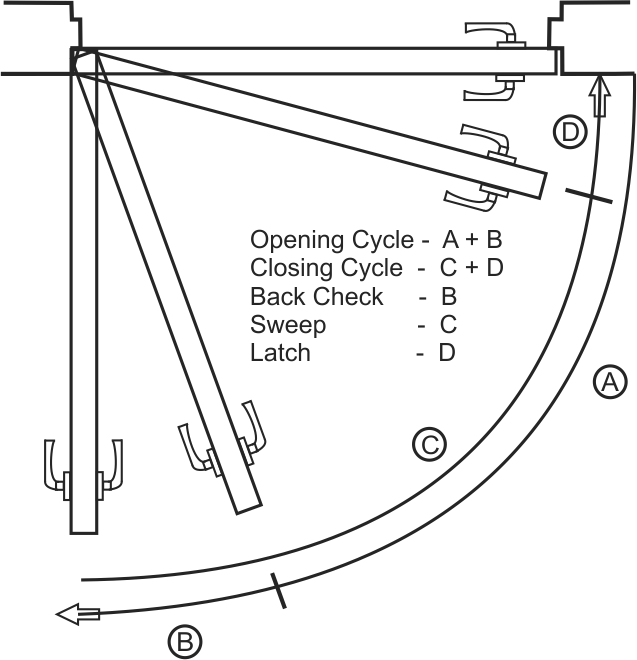

Door Closer Nomenclature

Closer Cycles

| Closing Cycle: | The entire length of travel from where the door is in the fully open position until the door is completely closed and latched |

| Opening Cycle: | The entire length of travel from where the door in the closed position until it reaches the fully open position including the back check cycle |

| Latch: | The last 15 degrees of the closing cycle before the lock engages the strike. This cycle allows the door speed to be decreased before it latches reducing the stress on the frame |

| Back Check: | The last 15 Degrees of the opening cycle before the closer reaches its maximum opening limit.This cycle slows the door down before it reaches the mechanical end of the opening cycle. |

| Sweep: | The distance between the end of the opening cycle until the beginning of the latch cycle |

Technical Note: Back check should never be used to replace an overhead stop or a physical door stop